Sludge Management

Sludge Management

Sustainable Sludge Management

- a fantastic resource for cultivation

Sludge from wastewater treatment plants is a fantastic resource for cultivation, but unfortunately, the sludge is often contaminated with heavy metals, most commonly cadmium, and unwanted organic substances at levels that may pose risks for cultivation. At eco:S, we use existing technology, pyrolysis, to convert sludge and other problematic residues into useful fertilizer products.

Turn your sludge into biochar and return phosphorus and carbon to the cycle

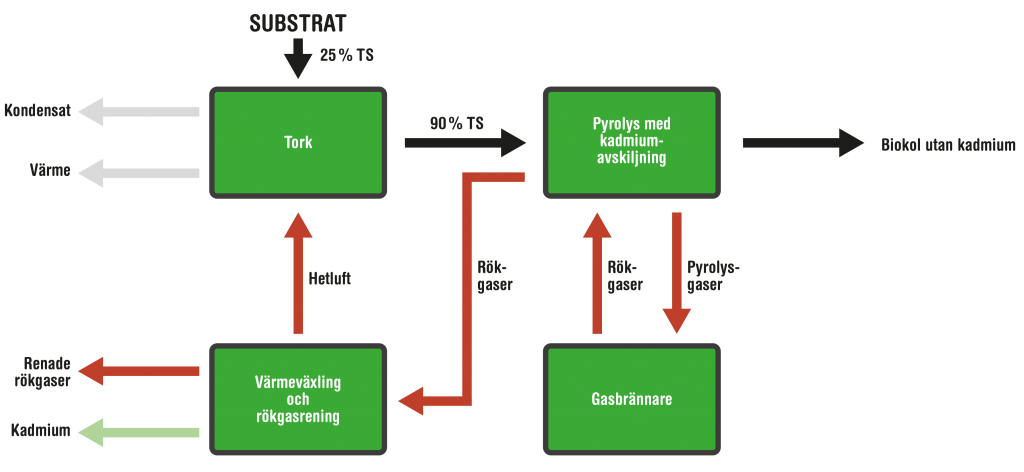

Input Substrate is dewatered sludge with a dry solids (TS) content between 20 and 30%. If the dewatered and digested sludge has a TS content of 25% or more, its energy content is sufficient to power both pyrolysis and drying processes. If the drying is done using steam drying, more than 80% of the supplied drying energy can be recovered.

During pyrolysis, the sludge is heated in an oxygen-free environment and converted into pyrolysis gases and biochar. The pyrolysis gases are energy-rich and consist of carbon monoxide (CO), hydrogen (H2), methane (CH4), and tar in gas form. The gases and tars can then be burned in a gas burner to provide heat for both the pyrolysis and the drying processes.

eco:S

With eco:S, more than 80% of the sludge’s cadmium content is separated. Unwanted organic compounds and pathogens are completely destroyed. Pyrolysis transforms the sludge into biosludge char, which is an attractive phosphorus fertilizer. This is how we ensure phosphorus recycling!

Want to know more?

Contact us through phone or E-mail or fill out the form below